In the autumn 2020, Kompani Giraff was granted funding from Kulturbryggan to develop a new circus discipline for aerial acrobatics, with the aim of extending the possible flight time. After a long process, we decided on the project name Swedish Aerial System, which has become a further developed rig application in aerial acrobatics.

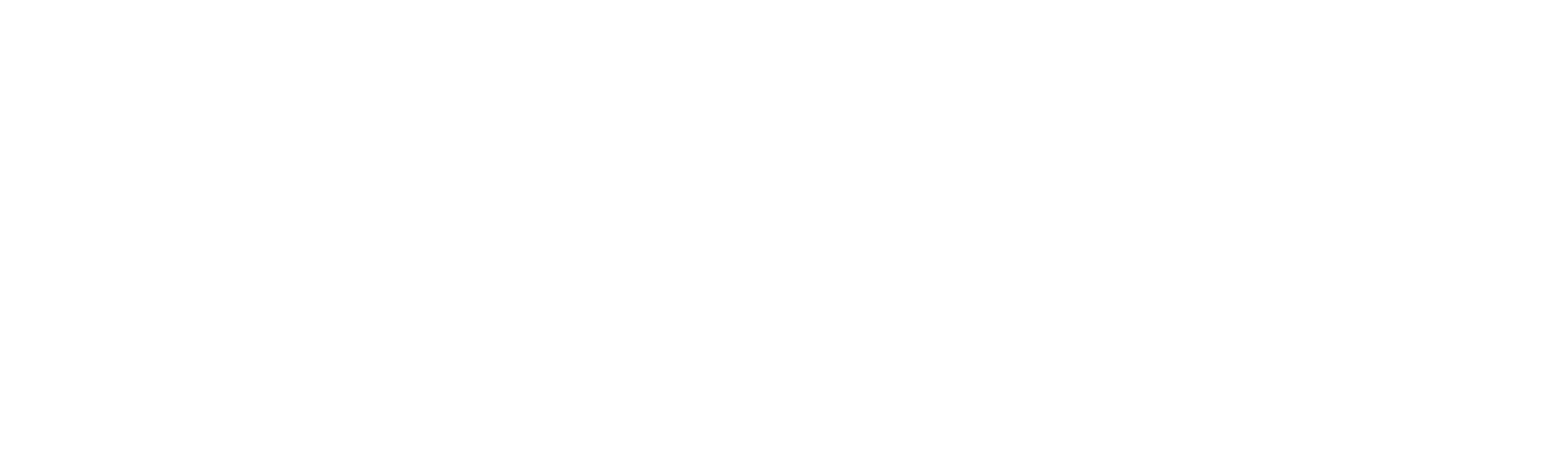

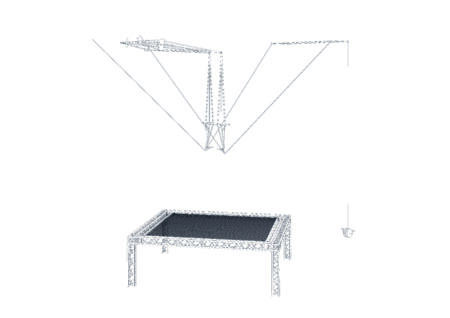

Under Stefan Karlström’s and rigger Matt Horton’s direction, we have created a net structure that functions as fall protection, and also has the capacity to launch the flyer into the air. This combination of catch net and trampoline, combined with the Korean Cradle, proved to be able to extend the flyer’s time in the air. We have also created a fold-down system for the trapeze and cradle, which significantly shortens the rigging time.

We now want to make the Swedish Aerial System available to those who are interested, which is why we publish drawings, pictures and videos from the work process on our website.

Riggers report

by Matt Horton

1. Brief

The project required design and construction of a system combining a safety net and korean cradle in order to prolong flight time of the artist and allow for a re-catch and continuation of an act.

General requirements were as follows;

→ Development of a cradle with no ground anchor points

→ Development of a safety net system which would also allow for the artist to be thrown back to the catcher i.e ‘Kickback system’

→ The korean cradle should be rigged and de-rigged in a timely fashion with minimal effort

Specific requirements were as follows;

→ The cradle should be rigged at a height to maximise the utilisation of the net system. (around 6m)

→ The requirement for the net was a fall of <5m to the net bed, to safely catch the artist (60kg) and provide a kickback to a similar height in order to prolong flight time for the artist.

→ The kickback system would preferably allow for a delayed reaction/activation.

2. Specification of rigging materials:

Korean cradle

Characteristic loading for the korean cradle in this case is ((60flyer+90base)*dynF3)) = 450kgf with peak force in the bottom 90deg of swing. With the self-weight of the cradle this gives a total characteristic load of 515kgf.

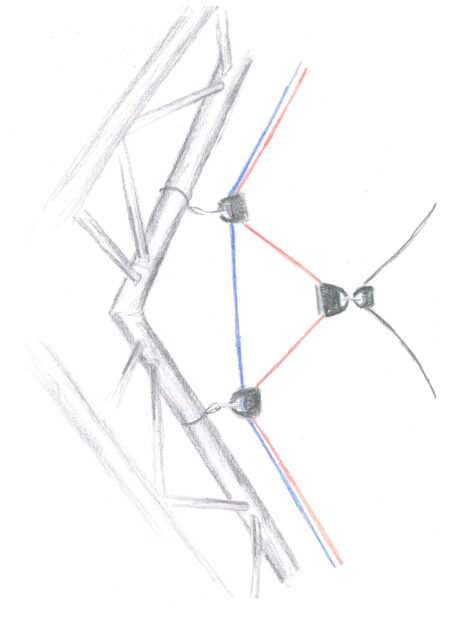

As the cradle was to be rigged from above, it was designed with struts that would act as both tension and compression members with a hinged frame to attach to the truss and allow for pivoting up into the truss grid. The guy lines would act as both stabilisation and additional primary load bearing components. Due to this 8mm dyneema sk78 was selected as the guy lines due to its static and high load capacity qualities.

To allow for fast rigging and tensioning of the guy lines, the two rear guy lines were tensioned at specific length using turnbuckles to ensure the cradle was vertical when tensioned.

The two forward guy lines were rerouted through pulleys to a hand winch system using a harken 40.2st self tailing winch with a working load of 850kg. This allowed for a rig of the complete system of under 10 seconds with 2 operators and a derig within a similar timeframe.

Net system

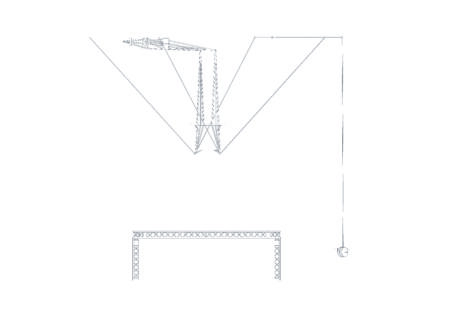

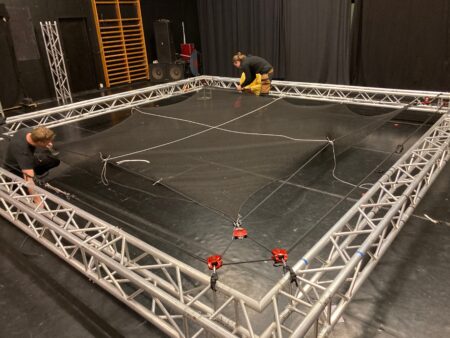

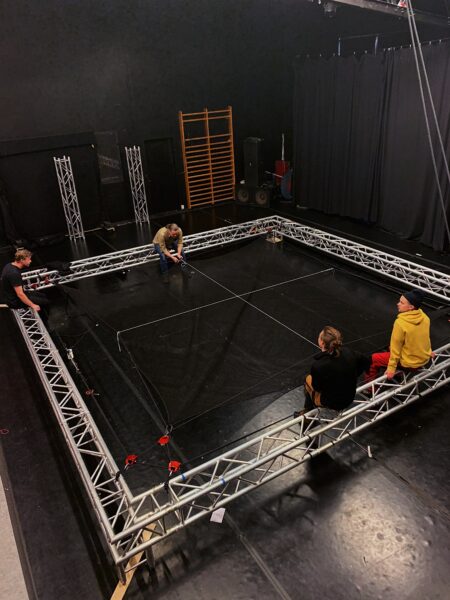

The net used for the system was a purpose built 5x5m fall arrest certified net. With a second hard rigged net under the first to provide a redundant fall arrest system.

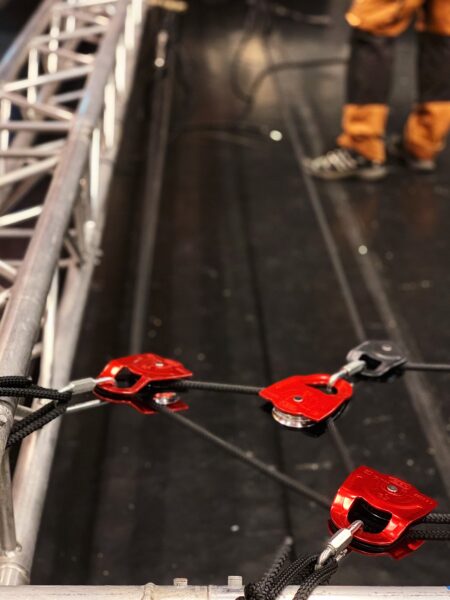

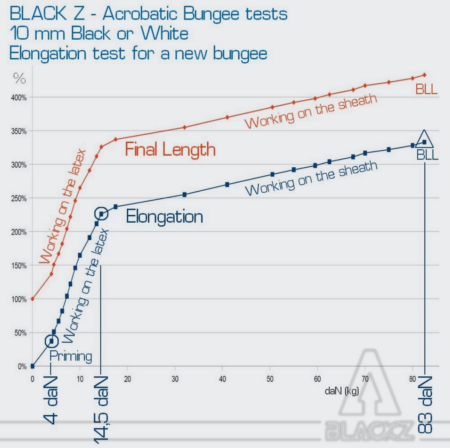

The bungee used was 10mm acrobatic bungee cord with cotton sheath with specified 225% elongation at 14.5kg per strand and minimum breaking load of 83kg per strand at around 300% elongation.

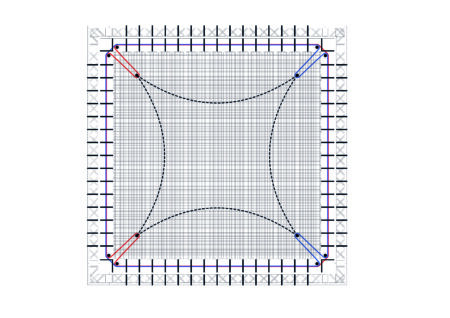

The bungee was arranged in soft shackle style slings of 60cm working length and used to connect the safety net to the truss structure with a double wrap. The knot used to attach the bungee slings was a diamond button knot, based on a carrick bend. This is used commonly in soft shackles, is resistant to compression and retains 100% of the ropes strength when used in the correct way Diamond Knot (Soft Shackle).

The bungee slings provided fall arrest and kickback through the net with a final effective working length of bungee of 50cm at 7kg pretension per strand. This allowed for 40-45cm of further elongation, allowing a catch amplitude of 1.4m in the centre of the net. Due to the level of impact force expected 18 slings per side were used giving a bungee responsive zone up to 252kgf per side with a combined central responsive zone of 504 kgf at and a factor of safety of 6 to minimum breaking load.

The expected peak impact force of the acrobat was 290kgf at 1m amplitude from a 5m fall. This was within the bungee responsive zone assuming a central impact on the net, and well within safety margins concerning material component strengths.

The truss used was eurotruss HD34 at a span of 6m, this fulfilled the required specification with an allowable loading of 373kg/m universal distributed load and allowable centre point load of 1120kg. The truss was raised 1.5m over the floor to allow for the required amplitude during a fall.

3. Inspection and operation

During operation and inspection some adjustments were made to the system to ensure safety. The connection point of bungee slings to the net required strengthening to make sure force distribution into the net was uniform. This was done with paracord woven into the net from each bungee insertion point. A second net was held in reserve in case the primary net showed wear, during the time in use of approximately 10-15 hours use the net began to show some signs of wear. A recommendation would be to remove the net after 20 hours of use in order to test its breaking strength and implement usage rules according to results, or research other alternatives for net material.

A similar recommendation would be made for the bungee, although this showed less wear during the same usage period.

During testing it became apparent that normal cradle technique was limited in its ability to utilise the potential of the system. Training time during the project consisted of 10-15 hours of testing. This provided enough time to create basic movements and to get used to the behaviour of the system, but further training would be required to realise its potential. For mid level tricks a further 30-50 hours would be recommended in order to safely progress.

During testing an additional system was installed to amplify the kickback of the net. Unfortunately the additional effect was difficult to time with manual operation and proved to add complications to the acrobats as it changed the behaviour of the kickback as to make it unreliable and inconsistent. We therefore decided to focus on developing a repertoire on the base system before moving forward with the development of additional mechanical aids.

With support of Kulturbryggan

People who have been involved in the process with Swedish Aerial System:

Stefan Karlström

Inventor, project manager, designer

Matt Horton

Rigger and technical assistant

Antoine Grenier

Rigging consultant

Janne Rosén SKH

Trampoline consultant

Wille Christiani

Rigging consultant

Joel Jedström

Manufacturing and technical feedback

Poly Nylin

Technical consultant

Viktoria Dalborg

Artistic director

Axel Adlercreutz

Graphic design and website

Mette Klouman

Structural feedback

Sus Soddu

Creative feedback

Isak Arvidsson

Artist and technical assistant

Anton Graaf

Circus performer and technical assistant

Sam Ramos Imbeau

Base in Korean cradle

Ronja Särkiniemi

Flyer in Korean cradle

Marie Binda

Flyer in Korean cradle

Ole Dampe

Base in Korean cradle

Giulia Scamarcia

Swinging trapeze artist

Fridjon Hrafnsson

Drawings in 3D

Rebecka Haglund

Documentation and drawings

Elisa Hedin

Documentation and drawings

Amanda Clausson

Photographer

Videos

Swedish Aerial System

With support of Kulturbryggan